Speed is all-important in Formula One – and the same applies to the production of the vehicle components. The Swiss Sauber F1 Team has been using EDM systems from Mitsubishi Electric for over ten years. These high-tech units machine even the most intricate workpieces quickly, accurately and in top quality – and have therefore become absolutely indispensable for Sauber.

Hard-wired for success.

Extreme requirements in top-level motor racing.

Everything is meticulously tidy in Alexander Simai’s workshop. Like a jeweller presenting his finest work, he has neatly arrayed his latest production items on his work bench: switches, screws, locking rings and chassis components. “These one-off items are employed in various places on our Sauber C35 Ferrari,” says Simai, proudly smiling as he picks up his most recent item, a titanium part for the wheel suspension. “Machining this is very complicated. You’re given a 3D model and you have to work out how to machine the component.” So far, Simai, whom his colleagues in the Swiss Sauber Formula One team approvingly call “Erosion Man”, has managed to solve every problem. But the requirements in top-level motor racing are exceptionally exacting. “You may get the design data for a component on a Friday evening, and it has to be out on the race circuit the next day. So you have to give everything you’ve got and be creative and quick at the same time.”

2016 Sauber F1 Team steering wheel model

Wire-cutting – an essential technology.

Innovative EDMs from Mitsubishi Electric help Simai to master his challenges. At its workshop in Hinwil near Zurich, the Sauber F1 team has been using high-tech installations from the world market leader for over ten years now. This partnership has become a cornerstone of the production strategy of the Swiss racing team, as efficient spark erosion facilitates machining feats that would be out of the question with conventional turning and milling methods. Components for the suspension, cockpit, steering column or brake pedals have to be produced quickly, with micrometre precision and in superlative quality so that they can bring to the circuit a vehicle that can compete speed- and safety-wise. Mitsubishi Electric machines satisfy these requirements. “With Mitsubishi Electric’s help, we have reorganised our production process so that we are at an advantage in terms of speed, flexibility and also costs. Both companies profit from cooperation: Mitsubishi Electric benefits in the marketplace and we benefit in production,” says Axel Kruse, Operations Director of the Sauber F1 Team.

The NA2400 and MV1200R wire-cutters and the EA12V die-sinker are the key items of production equipment in Hinwil. The mechanics use the high-tech systems around the clock and for almost all purposes – for the preliminary machining of safety-relevant parts and for the finishing of milled parts. Of the total of roughly 80,000 workpieces that they machine each year, 25,000 to 30,000 come off the EDMs. At the start of cooperation with Mitsubishi Electric in 2005, the workshop couldn’t have imagined how important this technology would become for them. “We started off with wire-cutting and at first only integrated certain steps in the existing process,” says Sauber Production Manager Ernst Keller. Today, they rely wholeheartedly on spark erosion. “It’s become absolutely essential for us. Without this technology, the processes that we’ve adopted today would hardly be feasible.”

Entrance door to the Sauber EDM department

Slashed set-up times and faster production.

The effectiveness of the Sauber approach is indicated by the race team’s consistently good performance over the years. Although the team has never bagged the big titles like Ferrari or Mercedes, it has established itself in the middle of motor racing’s Premier League and also made a name for itself as a talent factory. In the battle for the World Championship, drivers like Nick Heidfeld, Robert Kubica, Kamui Kobayashi and Sergio Perez have regularly picked up points. And in the 2015 season, the Sauber F1 team with its drivers Felipe Nasr and Marcus Ericsson achieved a commendable 8th position in the Constructors’ World Championship. And despite the fact that the abrupt departure of majority owner BMW from Formula One in the summer of 2009 severely shook the Swiss team. Nevertheless, team founder Peter Sauber, who bought back his baby after the BMW pull-out, got Sauber back on course. This was possible also because the team could continue to bank on the innovative capability of important technology partners like Mitsubishi Electric. Sauber’s engineers have never been short of high-tech components for the racing cars or for the company’s own wind tunnel. “That’s one of the great things about staunch partners like Mitsubishi Electric. We can rely on them to continue to refine their technology that we benefit from to such an extent,” says Kruse.

Ernst Keller, Production Manager, and Axel Kruse, Operations Director, with EDM-machined elements of the current Formula One vehicle

Even if Mitsubishi Electric has become a permanent fixture at Sauber today – getting one’s foot in the door with a motor racing team is anything but easy for an equipment supplier. The machine manufacturing competition is particularly strong in Switzerland, and many specialised firms have set up shop in and around Zurich. What’s more, the race teams traditionally keep the number of suppliers small for reasons of quality and safety. Formula One is a high-risk sport in which drivers and the people around them have to be protected. And this is why the teams want to exercise as much control as possible over their value generation. Sauber is no exception: “Our philosophy is to have on our premises all the components that, in the event of a defect, might result in harm to the driver, spectators or other persons. Process security is one of our primary objectives,” says Kruse. Precisely because of the need for ample reserves of safety, Sauber initiated business relations with Mitsubishi Electric in 2005, as the company has always had a fine reputation for EDM and industrial automation.

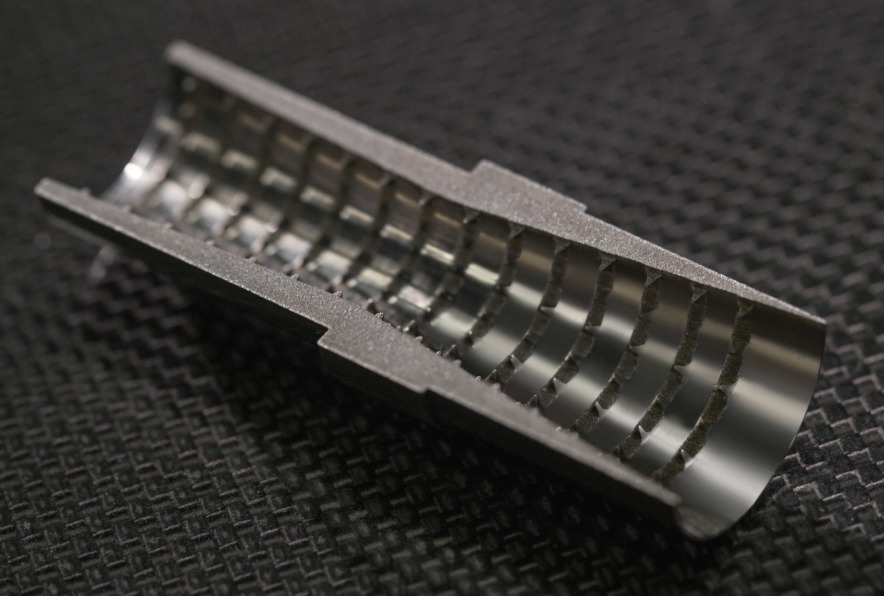

Auxiliary configuration for a 360° cut

Insights into turbulent motor racing history.

Connection for carbon rods

Two fascinating videos – by experts for experts.

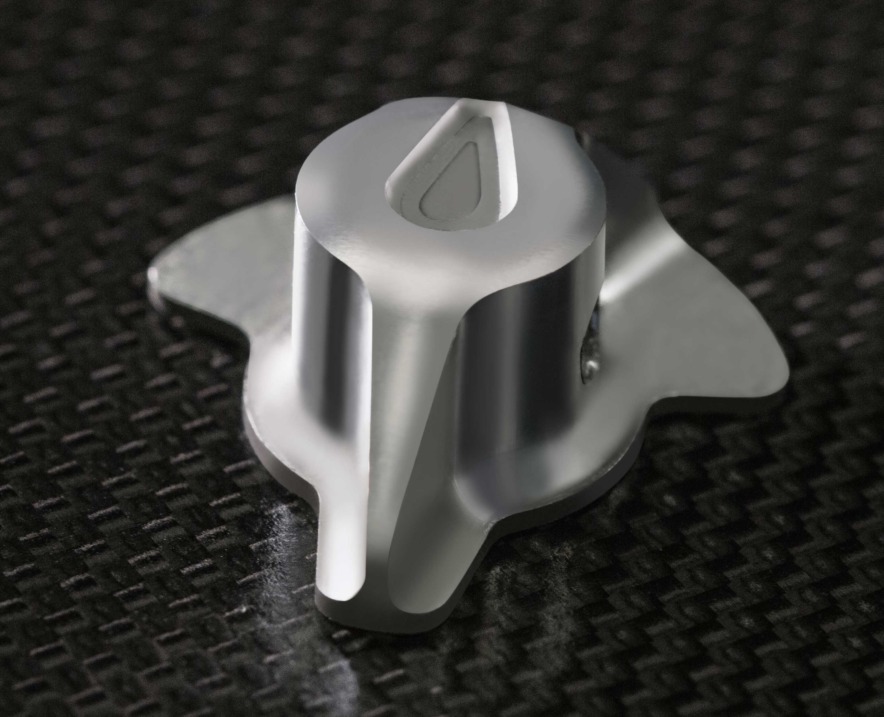

Steering wheel adjusting knob

Axel Kruse Operations Director

That’s one of the great things about staunch partners like Mitsubishi Electric. We can rely on them to continue to refine their technology that we benefit from to such an extent.

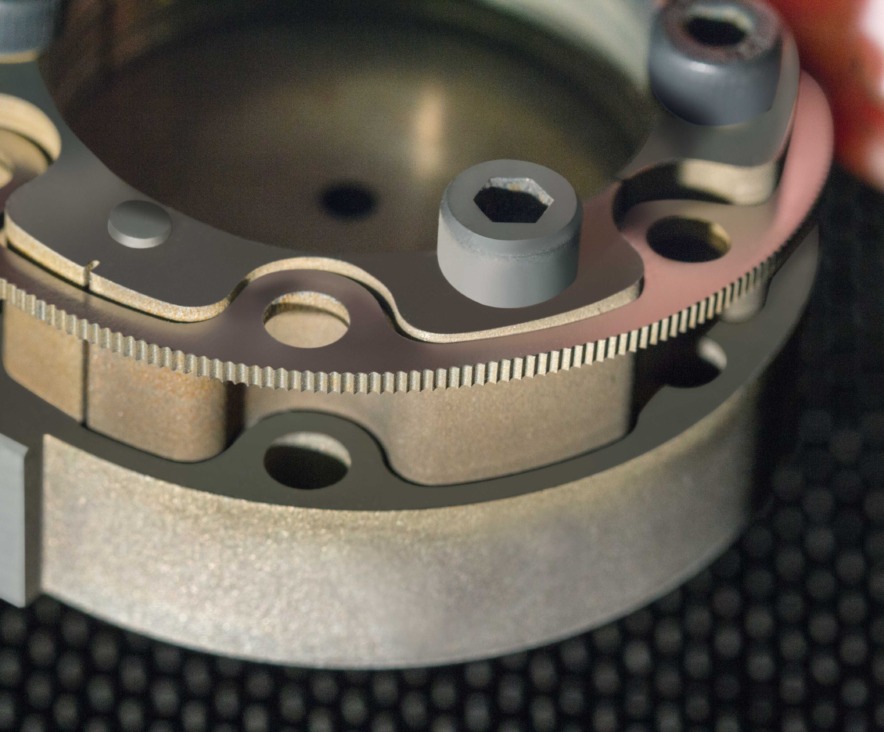

Die-sinking of titanium wheel suspension

Alexander Simai can no longer imagine his workplace without Mitsubishi Electric technology either. “It is spot-on, quick, easy to operate, maintenance-friendly and robust and produces outstanding results even in poor conditions,” says the skilled mouldmaker listing the advantages of the machines, before turning to the MV1200R whose performance he is particularly impressed by. “With the installed zero-point clamping system I can significantly reduce tooling time and thus improve productivity.” With the MV-R it’s possible to finish the job with fewer recuts – and with exceptional accuracy. “This also increases speed.” Furthermore, the MV1200R has a “brilliant automatic wire threader”. In the rare event of wire breakage, the machine rethreads the cutting wire right at the breakage point – in the kerf and without the dielectric having to be fully drained off. “This saves time and permits unmanned operation at night, even for the processing of components that tend to warp during machining.” The mechanics in Hinwil are happy to exploit this feature. “We set up vehicle components before leaving work and let them run on the machine overnight so that we can finish machining them the next day,” says Simai. So far there haven’t been any problems at all with the automatic threader. “The machine runs absolutely smoothly.” The ease of operation of the Mitsubishi Electric technology also goes well with Sauber’s speed strategy. According to Production Manager Keller, it is important for operators to be able to work at new machines productively without taking long to get used to them. “In our business, speed is of the essence. Our processes have to fall into place straight off. With Mitsubishi Electric, this is possible, as the machines are anything but highly complicated to operate.” In the Sauber workshop, thanks to hypermodern operating and programming equipment, work steps are highly streamlined. The engineers design the components on a 3D CAD system, and the mechanics, using CAM systems, then generate the NC cutting programs and transfer them finally to the machines via a DNC network. Efficiency is also boosted by the fact that the mechanics at Sauber are also responsible for programming, setting up and operating the EDM systems. This ultimately also creates scope for creativity, which also plays a big part in the Sauber process. How can a complex component be best machined on which erosion machine? With his wealth of expertise and passion, Simai will be facing up to precisely this challenge again tomorrow.

Right before the start of the race

Name and place of company:

Sauber Motorsport AG

Switzerland

Founding year:

1970

Managing director:

Monisha Kaltenborn

Number of employees:

some 350

Core business:

Motor racing – Formula One

Sauber Motorsport AG

Mitsubishi-Electric-Platz 1

Wildbachstrasse 9

8340 Hinwil, Switzerland

Tel +41 44 937 90-00

Fax +41 44 937 90-01

info@sauber-motorsport.com

www.sauberf1team.com

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com