Sharpen your productivity at GrindingHub, Hall 10, C71. Mitsubishi Electric

read more

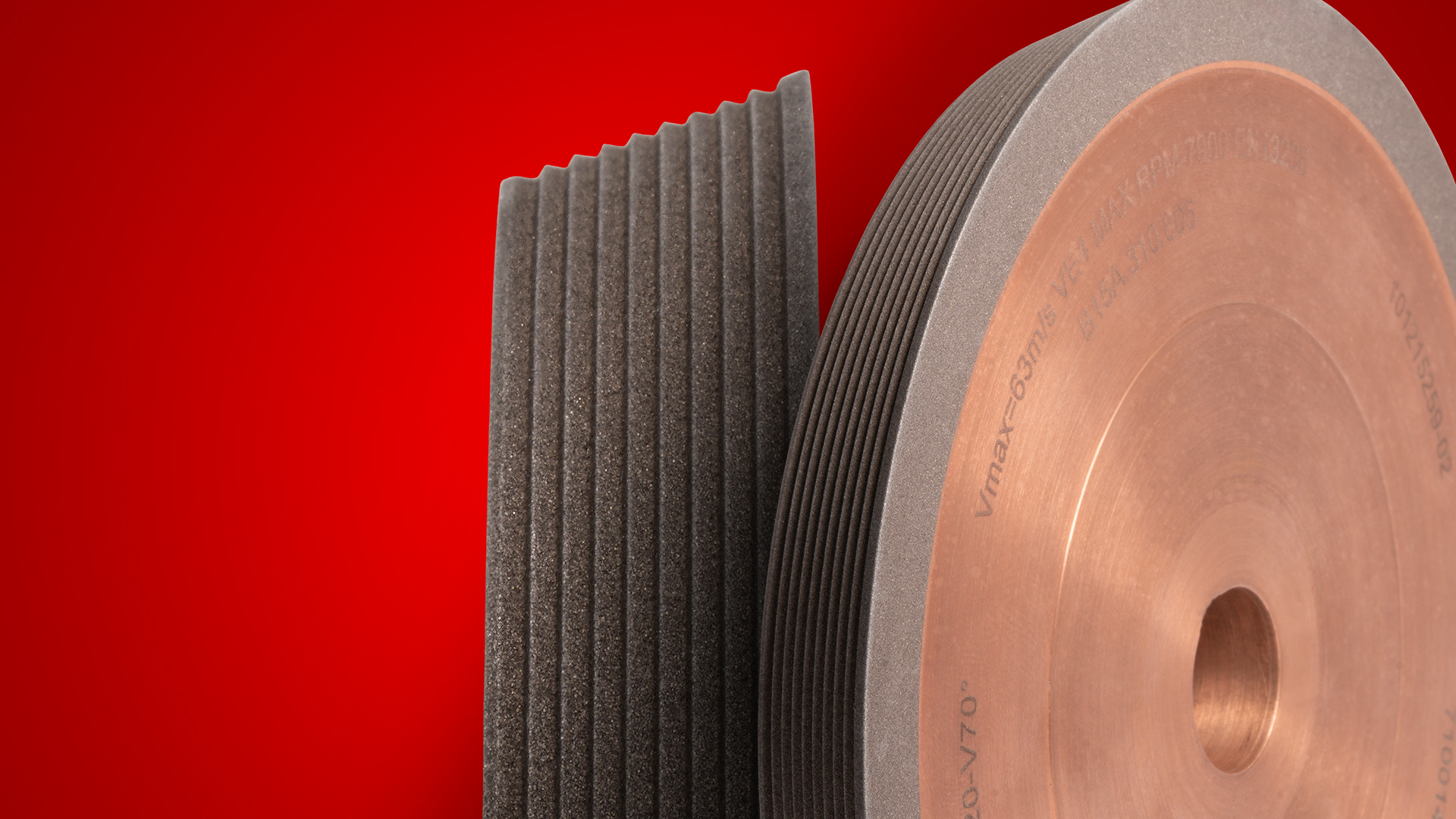

Exploit the advantages of metal-bonded grinding wheels in the grinding process

In the grinding of tungsten carbide, ceramics and hardened steels, metal-bonded grinding wheels have huge advantages over the grinding wheels with synthetic resin bonds currently in frequent use. They are much more dimensionally stable and permit significantly higher grinding feed rates – for previously unattained productivity.

The constant challenge of boosting precision and effectiveness while reducing costs can be achieved with metal-bonded grinding wheels. The previously highly elaborate dressing process can now be superseded by wire EDM systems with the V350 generator from Mitsubishi Electric.

Experience live on site how Mitsubishi Electric can help you to significantly increase your productivity and efficiency.

Visit us at Hall 10 Stand C71

Our team ist waiting for you

Unfortunately, you are not planning to visit GrindingHub this time, but are still interested in how you can substantially increase your productivity and profitability? No problem!

The grinding wheel is profiled to your wishes. Test the feed rates and service life on the real-life job. You’ll be delighted with the superior productivity and potential for savings.

For only €199 per disc – the offer is limited to one grinding disc, max. diameter 150 mm, per customer.

Yes, I am interested to test that, send me more info

Discover how spark erosion dressed grinding wheels can revolutionize your productivity: up to 280% more feed rate, significantly longer tool life and the production of previously impossible geometries - simply and automatically.

Learn from leading experts such as Prof. Dr.-Ing. Bahman Azarhoushang from Furtwangen University and industry leaders such as Riegger Diamant, Adelbert Haas and Mitsubishi Electric how this technology enables complex profiles and optimal microtopographies, increases productivity and offers a real competitive advantage.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com